Partnered research project

Coordinator : LNE

Period: November 2020 - September 2022

Partners: LNE, Citeo, INRAE, CTCPA, IPC

Context

The current regulatory context is encouraging and pushing manufacturers to bring out packaging incorporating more recycled plastic. One of the solutions implemented by manufacturers on trays is ABA tri-layer technology using:

- A layer B of recycled PET, often not decontaminated via an EFSA-recognized process and therefore not suitable for food contact .

- Virgin PET A-layers act as functional barriers, i.e. they are supposed to limit the migration of potential contaminants from layer B to the packaged food.

This application currently has no health guarantees for marketing in Europe, and no recommendations for good practice. The study is of very great generic interest to the public, authorities and industry on issues of a priori assessment of the risks of food contamination by these trays and its interpretation in terms of consumer exposure.

Objectives

European regulations (e.g. règlement (EU) n° 10/2011) recognize the use of calculations for demonstrating the conformity of plastic materials and articles in contact with foodstuffs. Modelling can also be used in other contexts, provided it is based on scientific literature and documented methods. This latter approach is followed by risk assessment agencies (ANSES, BfR, EFA, FDA...). However, it should be remembered that situations of danger or non-compliance, even if they can be identified by computational means, must benefit from experimental proof.

In this project, we propose to use mathematical modeling to answer three types of questions, which will be addressed with different levels of refinement depending on the conclusions obtained during the different stages of the project:

- Overall assessment of the risk of migration by target substances and comparison with acceptable thresholds, taking into account the same overestimation factors as those used for demonstrating compliance;

- Identification of the critical steps that contribute most to contamination of the packaged food under consideration. This is an approach developed [see article] during the ANR SafeFoodPack Design program (2011-2014) compatible with the 2023/2006/EC framework regulation on good industrial practice. The iterative calculation method that supports it is capable of propagating sources of uncertainty and is able to take into account realistic scenarios at the scale of an industry. Severity (level of migration with respect to acceptable thresholds) can be verified experimentally for the most critical stages;

- Search for possible safe conditions for the consumer, taking into account formulation, coextrusion and shaping conditions and usage, material geometry, food properties. To identify the "safe domain", refined models (thermodynamic and transport properties) verifying the state of the art will be used.

The project will strive to make the best possible use of data from the literature and mechanistic descriptions of the phenomena (e.g. PET properties in the molten and solid states, temperature kinetics during shaping and coupling with material transfers, contact and non-contact transfers, chemical affinity for the food) to obtain a realistic risk assessment. Experimental validations are recommended: i) to validate critical points based on experimental facts, ii) to measure overestimation factors on transferred quantities, iii) to confirm conditions that would lead to low or non-detectable migration. The project will produce in the report an independent, argued and nuanced analysis on the generic issue of using any recycled material between two layers of virgin PET in trays.

The project brings together five partners: CITEO, LNE and INRAe under the label "UMT SafeMat", IPC the CTCPA. A Monitoring Committee made up of stakeholders (tray manufacturers, trade associations, scientific experts, end-users, etc.) will be set up to support the project.

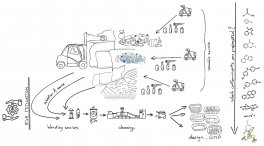

Methodology

The project is broken down into four main complementary strands, which can be carried out relatively independently and sequentially. Component 1 is purely computational. Components 2 and 3 will provide the necessary validation. Component 4 concerns extensions to PP and dissemination of the project.

Stream 1. Migration risk assessment and comparison with acceptable exposure thresholds for typical tray applications (e.g. fresh fruit and vegetables, cheese, meat and charcuterie) with regard to likely scenarios of B-layer contamination. Processing, storage and use stages will be considered, as well as the consumer profile (adults, children).

Strand 2. Characterization of recycled PET deposits and refinement accordingly of Stream 1 scenarios.

Stream 3. Carrying out validation tests using trays implemented on a semi-industrial scale with a B layer formulated with model contaminants. Transfer values at the main stages (shaping, contact) will be used to validate the extrapolation capability of the models set up in part 1.

.Strand 4. Recommendations; scientific analysis and removal of technical barriers using PP as a functional barrier; valorization of results and communication.

.