Project HORIZON – IA n° 101059923

Coordinator: Centre technique industriel de la plasturgie et des composites (IPC)

Period: 09/2022 – 02/2026

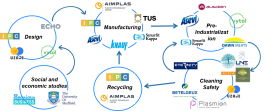

Partners: ACTIA (Third-parties: CTCPA, LNE), Orca Services, UZAJE, Knauf Industries Gestion (France) ; Aimplas, Betelgeux SL, Ausolan, Plastico Vicent SLU (Spain) ; Technological University of the Shannon, Dawn Meat Group (Ireland) ; Searious Business BV (Netherlands,) ; Vytal, Plasmion GMBH (Germany) ; University of Sheffield (UK)

Summary

BUDDIE-PACK is a circular economy project aiming at implementing a systemic approach for the large-scale deployment of reusable plastic packaging (RPP) based on a multidisciplinary approach combining social, technological and economic innovations. The project will take advantage of behavioural innovation to promote consumers' acceptance of RPP by analysing drivers and analysing consumers’ psychology of reuse. Sound synergies with technological innovations will be developed to manufacture packaging fulfilling the demanding requirements of RPP based on innovative designs and recyclable materials. The project will focus on innovative cleaning solutions to guarantee the safety of consumers against the possible contamination and ageing of RPP during their repeated use, and the durability of the functional properties up to 300 cycles. Viable economic models will ensure the sustainability of the proposed solutions thanks to the profitability of stakeholders throughout the value chain, including solutions based on social & solidarity economy models.

The project outcomes will be demonstrated under the supervision of RPP manufacturers and users, logisticians, cleaning and recycling experts through 6 mass market business cases in real environment at TRL8. An unprecedented cleaning pilot line dedicated to RPP and allowing scale economies will be set up. Policy recommendations and pre-standardisation activities on RPP designs and cleaning protocols will prepare the markets for the mass deployment of RPP. Preventive measures will be put in place to eliminate any release of microplastics during RPP use. The project will avoid each year the production of nearly 544 M of single-use packaging (SUP), reduce the consumption of virgin plastics by 103 ktons, of water by 1 B to 18.5 B litres, avoid 303 660 ktons of CO2 emissions, 37 ktons of microplastics leaking in EU seas.

Context

“10–20% of plastic packaging could be reusable by 2030, equating to 50% of annual plastic ocean waste.” Reuse is an ecological and circular alternative to SUP enabling to reduce the production of wastes by extending the lifetime of the packaging. In any waste management hierarchy reuse is preferred over recycling since it reduces waste, contributes to resources preservation and is much less energy intensive. Reuse is a cornerstone of the EU plastics strategy targeting 100% of reusable or recyclable plastic packaging by 2030.

Objectives

The general objective of BUDDIE-PACK is to develop and demonstrate sustainable strategies for RPP in the food and cosmetics/personal care sectors. To achieve this goal, BUDDIE-PACK will deploy a threefold innovation strategy combining technological, social and economic innovations that will enable to build a sustainable circular economy model for RPP in a wide field of mass market applications directly supporting the EU Plastics Strategy and the Packaging and Packaging Waste Directive (PPWD) revision. The project will carry out large scale demo trials in a large range of applications to validate the models. The project aims at standing as a reference to be disseminated and widely used in Europe and beyond through policy and pre-normative activities in several European countries.

The BUDDIE-PACK project has seven specific objectives:

Objective 1: Developing technological solutions for the design and manufacture of packaging with the appropriate functional properties required for reuse.

Objective 2: Understanding consumers’ expectations and acceptability with regards to RPP and assessing drivers to change their behaviour to widely adopt it (e.g. commitment to return the packaging, acceptation of already used packaging …).

Objective 3: Developing sustainable business-driven strategies offering profitable economic models to RPP.

Objective 4: Ensuring safety, risk management, and reduce microplastics release in the environment.

Objective 5: Carrying out large scale TRL8 demo trials to validate RPP along the value chains from a technical, economic and social point of view.

Objective 6: Promoting reusable packaging across the EU.

Methodology and expected results

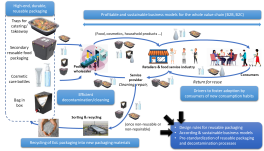

The BUDDIE-PACK project will develop solutions for RPP in order to substitute SUP in 6 market applications (rigid take-away food trays, rigid refill bottles, semi-rigid catering trays, semi-rigid skin pack for meat distribution, reusable semi-rigid delicatessen packaging, recyclable flexible Bag-in-Box® for the sale of personal care loose goods), encompassing daily-life uses of plastic packaging for food and home care goods. Business cases will cover two possible methods for the packaging return: on site, which allows excellent traceability; from home, which presents an additional security risk since consumers’use at home is not traceable. RPP decontamination and safety control strategies will differ accordingly: site returns allow more flexible decontamination measures while home returns require tighter decontamination and monitoring.

For each market application, 4 challenges must be completed:

1. Determining the drivers to foster adoption by consumers of new consumption habits. Reusing packaging implies an important change in consumption habits, for consumers to be willing to use a packaging used before by somebody else, and also to return the used packaging and not throw it away.

2. Designing and manufacturing high-end, durable, reusable, and recyclable packaging. Going from single-use to reusability cannot be achieved without redesigning packaging to make them resistant, aesthetically good-looking, highly functional, fully safe in respect of food and cosmetic goods. Materials, shapes, thicknesses, recyclability to manage the packaging end-of life, costs need to be considered. Packaging must be recyclable once they can no longer be reused. This means they must be sorted out, even their low volumes make them not adapted to current recycling streams.

3. A reusable packaging must be completely safe for consumers, necessitating thorough cleaning and decontamination, adapted to the design of the reusable packaging.

4. Each market application must follow a sustainable business model for every involved stakeholder. From the manufacturer to the retailer, including distributors, consumers and recyclers, everyone must find an economic benefit in using a reusable packaging.

The BUDDIE-PACK project will deliver 3 key results:

1. A public set of design rules considering the uses and stakeholders needs from six targeted mass market applications, representative of the overall market requirements.

2. Six business-driven models for RPP validated and demonstrated at TRL8, promoting common items and replicability levers to other countries and applications.

3. To guarantee the adoption of the innovations and strategies defined within BUDDIE-PACK all developments will be supported with pre-normative and policy actions in several European countries.

Organisation

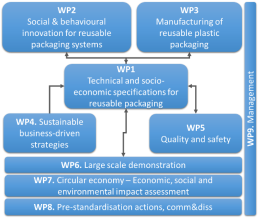

The BUDDIE-PACK project is split into nine work-packages. The project is centred around WP1 which will establish the design rules based on a first analysis of the socio-economic and policy framework, and market requirements related to RPP, which will result into a first design set to feed three other WPs (WP3 – materials and manufacturing processes for RPP, WP4 – business models and WP5 - quality and safety technologies). WP2 is dedicated to the understanding of the consumers’ behaviour. The results of WP2 will enable an iterative improvement of RPP specifications and therefore of their designs, materials, economic models and quality / safety controls. This will lead to a second set of design rules; a final round of packaging will be manufactured in WP6 for large scale demonstration which in turn will allow to update and finalise the design rules in WP1. WP7 and 8 will run in parallel to assess the project results (environmental, social and ecological evaluations) and prepare the markets (pre-standardization, dissemination, communication).

Impacts

- Increased deployment and market uptake of innovative solutions

- Increased reuse, recyclability and upcycling of packaging and single-use plastics

- Significant reduction in over-packaging and single-use plastics in consumer goods, food packaging and humanitarian relief items

- Significant reduction in packaging waste and single-use plastic waste

- Significant reduction in management costs for the respective waste streams

- Significant reduction in the release of microplastics from packaging and single-use plastics into the environment