Today, the contamination of foodstuffs by substances present in cardboard cartons or boxes is well established. The presence of mineral oils has been demonstrated in a wide variety of foodstuffs. They can be contaminated at any point in the processing or supply chain. The product groups most likely to be contaminated by these substances include cereals, rice, flour, pasta...

Studies and an EFSA recommendation

The contamination of food packaged in packaging systems combining a cardboard case or box and a plastic bag by substances derived from recycled fibers was revealed by a study conducted by the German Federal Institute for Risk Assessment (BRF) in 2010. This study was the subject of a paper in 2013 (Biedermann et al., 2013).

In October 2015, the FoodWatch organization published the results of their study and alerted public authorities to the possible contamination of certain food categories by mineral oils derived mainly from recycled paper and cardboard.

The mineral oil fraction concerned is essentially composed of complex mixtures of hydrocarbons (between 10 and 35 carbon atoms) of fossil origin. Two categories of these compounds have been identified in contamination phenomena:

- the MOAH (Mineral Oil Aromatic Hydrocarbons)

- the MOSH (Mineral Oil Saturated Hydrocarbons)

Although they have high molecular weights and low vapor pressures, these compounds, under specific temperature and storage time conditions, are likely to migrate to the food. These migrations also depend on the type of packaging used (primary packaging), which can play a more or less barrier role with regard to these phenomena.

While no regulations currently exist on acceptable quantities of these mineral oils in food products, in June 2012, EFSA (European Food Safety Autority) established recommendations based on an Acceptable Daily Intake (ADI) of 0.01 mg/kg body weight, i.e. a limit in food of 0.6 mg/kg.

Development of analysis methods

In order to define such limits or set up suitable analysis methods, it is essential to correctly describe the phenomena involved and thus set up control tools (prediction tools, for example) in order to design safe packaging.

This is what the Laboratoire national de métrologie et d'essais (LNE) has been working on in partnership research programs (for example, the projects "SafeFoodPackDesign" and "MINOILS") in order to demonstrate with an experimental set-up the contamination of food indirectly by mineral oils and to propose a simplified solute-independent predictive model.

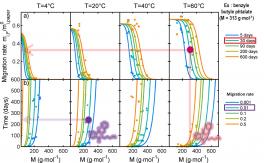

One of the main results of the projects is the construction of iso-contamination / time / temperature / molecular weight abacuses (see figure 1) on the basis of experimental data obtained for various packaging temperatures and a studied geometry. These abacuses make it possible to predict, for a known initial concentration of a solute in a material, its contact time for a given temperature, and thus to relate contamination levels to actual conditions of use (product shelf life and storage temperature).

The main results of the projects are the iso-contamination / time / temperature / molecular weight abacuses based on experimental data obtained for various packaging temperatures and a studied geometry.Given the questions and growing demand from the food industry and major retailers regarding contamination of foodstuffs by mineral oils, LNE is therefore proposing to support the various parties involved in the manufacturing and supply chain in the implementation of their materials intended to come into contact with foodstuffs.

The tools developed in the course of partnership research programs will make it possible to assess product contamination by these substances right from the material design phase.

List of scientific articles

Update date: March 2017

Would you like us to help you address the health and safety of your materials?

food contact specialist

To help you:

- Know the regulatory requirements for materials and articles intended to come into contact with foodstuffs;

- Provide proof of compliance with these requirements;

- Integrate food safety concepts into innovation and research / development.

LNE offers solutions and support in all phases from packaging design to production, and adapts methodologies and solutions to your needs.

Discover our services: technical assistance/consulting/engineering, monitoring, analyses, training, certification