The classic approach to demonstrating the conformity of a material or object in contact with food consists in analyzing the migration of constituents in food simulants. This approach sometimes comes up against practical difficulties such as the lack of an analytical method or the time needed to obtain results. In recent years, new modeling tools based on mathematical representations of migration phenomena have been introduced. These not only enable migration levels to be predicted, but also allow substances, materials and even stages in a process to be prioritized according to their criticality, more rapidly and at lower cost. Although current regulations authorize modeling to establish the conformity of materials and objects, these tools are still little known to operators.

European legislation difficult to apply

For several years now, the European Union has been harmonizing the regulatory requirements applicable to materials in contact with food, with the aim of guaranteeing food safety and preventing the contamination of foodstuffs by substances originating from packaging.

.This ongoing harmonization is also intended to enable the free movement of goods and, as such, European legislation is built on a chain logic and prescribes requirements by group of materials. Although the ultimate aim is to minimize food contamination, in practice compliance is often assessed by partially taking into account contaminants from the entire supply chain.

In principle, European legislation is clear: a material "must not present a danger to human health" (Article 3 of Regulation (EC) No. 1935/2004). This principle applies to the 17 groups of materials precisely described in the regulations. However, the implementation of this requirement is more complex for operators, due to the absence of specific application measures for 13 of the 17 groups of materials. For some of these materials, there are provisions applicable at national level. However, the regulatory texts concerned are sometimes old and do not take into account the evolution of technologies and methods of use of materials in contact with food. Moreover, even for the materials covered, part of the demonstration of conformity relies on risk assessment carried out under the responsibility of operators: This is the case for substances in plastics, some of which are not included in the positive list (colorants, solvents, substances in inks, glues and adhesives, and neoformed substances).

A complex and costly assessment of packaging safety

To assess the safety of materials and packaging intended for contact with food, the means and strategies usually employed have limitations that don't always allow the demonstration to go all the way. Few methods for measuring specific migration have been standardized, and the cost to laboratories of developing new methods is high. Most of the time, analyses are carried out on the basis of rules laid down by regulations, using standardized conditions which do not correspond exactly to actual conditions of use. Lastly, controls are carried out at the end of the chain and do not take into account all contamination risks (such as "set off" decal effects).

.Modeling tools to meet this challenge

Based on this observation, INRA launched a research project involving LNE and other partners within the ANR collaborative project "Safe Food Pack Design" to develop new approaches and tools to better demonstrate the safety of food packaging. This work has already made two modeling tools available to market operators:

- 1];

- FMECAengine [2] (developed as part of the ANR project "Safe Food Pack Design").

Based on the phenomena involved in the contamination of food by materials (diffusion of substances into the packaging material and sharing of substances between the material and the food), the SFPP3 modeling tool can predict the contamination of a food by a chemical substance. The input data for the calculation involve the characteristics of the packaging, the transfer properties of the substance and the conditions of use of the packaging, i.e.:

- the contact surface of the packaging with the food;

- the concentration of the substance in the material;

- the volume of material and its density;

- the volume and density of the food;

- the diffusion coefficient of the substance in the material and in the food at a given temperature;

- the partition coefficient of the substance between the material and the food;

- the contact times and temperatures between the material and the food.

Output data are presented in the form of a curve showing migration kinetics (concentration of the substance evaluated in the food as a function of contact time with the material) and as a profile of substance concentration as a function of material thickness after the chosen contact time with the food. With these results, it is possible to predict the contamination of foodstuffs by substances, particularly at the best-before date in the packaging. The migration values obtained can then be compared with accepted regulatory thresholds (SML in mg/kg of food).

SFPP3 is open source and has been developed, in particular, as a means that can be used, in the European Union, to demonstrate the conformity of packaging intended for contact with food (EU Regulation No. 10/2011 concerning plastics). This method, recognized by the authorities in charge of market control, does not replace migration analysis methods, but complements them by providing the computing power of a tool that can be parameterized and used in the absence of an analytical method to demonstrate packaging conformity. On the other hand, the migration values obtained do not allow us to conclude that materials are non-compliant, as they overestimate food contamination (the calculation's starting hypotheses are based on worst-case scenarios and maximize migration).

In order to be able to better assess food safety within a process logic, the "SafeFoodPack Design" research program has extended the SFPP3 tool. This tool is based on the use of a hazard and risk analysis method known by the acronym AMDEC (Analyse des Modes de Défaillance, de leurs Effets et de leur Criticité) or FMECA (Failure Mode Effects and Criticality Analysis). This method, originally developed in the 1940s by the US military, was taken over by NASA in the 1960s for the Apollo program, to be applied to food suppliers under the name HACCP (Hazard Analysis and Critical Control Points).

The 2th modeling tool, called FMECAengine, performs calculations based on real cases of packaged food products. Its aim is to analyze a failure (the migration of a substance) on the basis of a severity level (the standardized migration level based on thresholds linked to the toxicology of substances) in order to establish a criticality level based on various parameters such as the nature of the packaging components, the chemical substances contained in the materials, the geometry of the articles and the process stages.

Three types of practical applications are already being used as part of the research program:

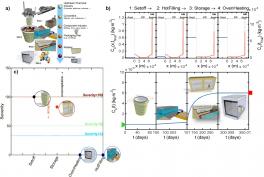

- severity assessment of an industrial stage: The aim is to prioritize the risks associated with all the practices and conditions of use of materials, from the industrial storage of packaging components through to the preparation of packaged food by consumers (see figure 1);

- comparing different packaging designs: This involves introducing additional constraints of the "usage properties" type into the packaging design process. Product safety is then constructed by taking into account other packaging characteristics such as mechanical properties or gas permeability;

- assessment of food contamination by substances potentially present in its packaging: based on scenarios corresponding to real cases of packaged foodstuffs, a statistical distribution of overestimated diffusion coefficients is calculated in order to assess the risks of contamination by substances potentially present in the formulation of packaging materials.

FMECAengine aims in particular to better meet the obligation, placed on market operators in Regulation (EC) No. 2023/2006, to implement good practices and control the risks of food contamination by packaging.

Within the Unité Mixte Technologique ACTIA "SafeMat : Matériaux-Sûrs", LNE is contributing, along with INRA and AgroParisTech, to various developments of the: three-dimensional transfer modeling tool, modeling in the presence of flows (pipes, pumps, industrial equipment, etc.), repeated use of materials.), repeated use of materials. The use of these tools can be extended to other applications such as product packaging cosmetics, pharmaceuticals or biotechnologies. Transfer modeling data can be reconciled with packaged product consumption data to assess consumer exposure to certain chemical substances.

Useful links

List of scientific articles

(64):45-8.

Update date: March 2020

Would you like us to help you address the health and safety of your materials?

food contact specialist

To help you:

- Know the regulatory requirements for materials and articles intended to come into contact with foodstuffs;

- Provide proof of compliance with these requirements;

- Integrate food safety concepts into innovation and research / development.

LNE offers solutions and support in all phases from packaging design to production, and adapts methodologies and solutions to your needs.

Discover our services: technical assistance/consulting/engineering, monitoring, analyses, training, certification, r&d